Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

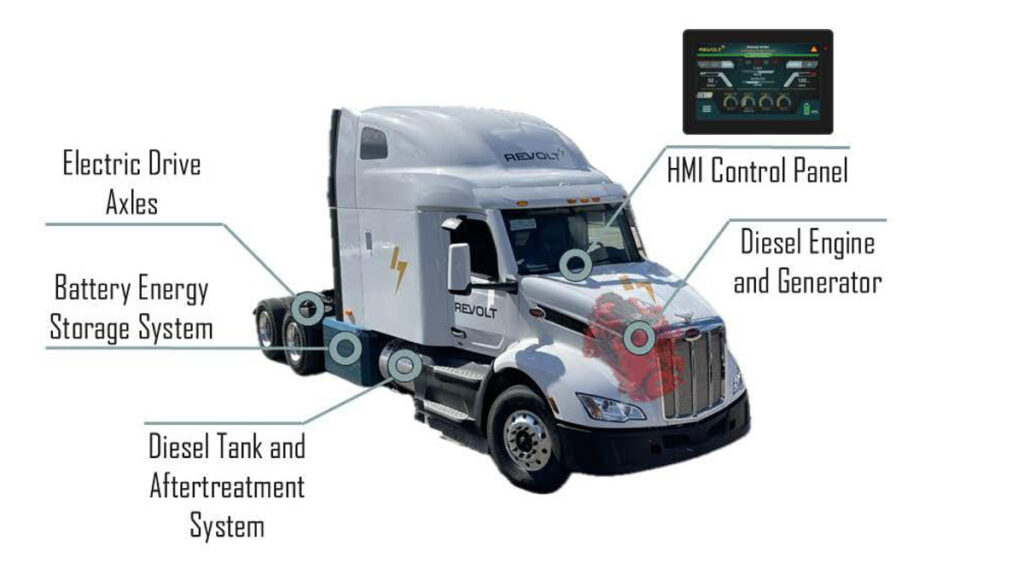

Why throw away a perfectly good Class 8 tractor for a new battery electric truck when you can re-power it at half the cost and pay for the upgrade in a little over a year? That’s the business proposition ReVolt is offering the trucking industry. The company has created a replacement powertrain for Class 8 trucks. Think of it as a version of the Voltec system GM created for the Chevy Volt more than a decade ago. Like the Voltec, the ReVolt system is a series hybrid, which means the driven wheels are powered by an electric motor that gets its electrons from a battery. That battery can be recharged from an external power source just like any battery electric vehicle, but Class 8 trucks often need to go further than they can travel on battery power alone. That’s where the ReVolt system comes in. It includes an onboard internal combustion engine to power a generator that sends electrons to the battery while driving.

The differences from the Chevy Volt are significant. The ReVolt powertrain boasts a total of 670 horsepower, 3,500 lb-ft of torque, and a GVWR of 130,000 pounds, meaning it is fully capable of hauling the heaviest loads up the steepest grades. It features a 210 kWh battery supplied by CATL and has a total range of 1,200 miles. The drivetrain supports “hoteling,” which means the truck can go an entire week with all of its critical systems functioning without having to run the generator.

There are other advantages. The battery can provide 24 kW of 3-phase power in either 240 or 480 volts to support industrial equipment such as welding machines, HydroVac machines, dry material handling pumps, and hydraulically operated equipment. While stationary, the battery can deliver 200 kW (400 kW peak) of power to remote applications where there is limited or no access to power sources, such as oil field drilling and fracking applications.

ReVolt works with multiple suppliers to source the best domestic component options, including Flodraulic, a company that has global expertise in fluid power as well as electrical and mechanical technologies, and specializes in the integration of low-voltage and high-voltage systems in heavy-duty machinery. It is one of the largest Danfoss suppliers of Danfoss equipment in the world. Danfoss Power Solutions boasts that it has the technology and the expertise to transform mobile and industrial machinery so they can lead the way to a more sustainable future by increasing machine productivity and efficiency while reducing or eliminating emissions.

ReVolt Range Extender Engine

Here’a the part where CleanTechnica readers may feel a little uneasy. The ReVolt powertrain uses a diesel engine sourced from Scania to power the onboard engine. Diesel engines from other manufacturers may be used in some trucks as well. Is that the ideal situation? For long-haul, heavy-duty trucks, it may well be. The important statistic we haven’t shared with you yet is that ReVolt claims its powertrain will save truckers 40 percent on their fuel costs.

According to trucking industry news source Bobtail, a typical Class 8 diesel tractor drives 62,169 miles in a year and averages about 6.5 miles per gallon, which makes the total consumption of diesel fuel each year 9,564 gallons. In 2021, there were approximately 4 million Class 8 trucks on the road in America which consumed around 39 billion gallons of diesel fuel. Taking the average fuel economy of 6.5 miles per gallon, that means the average owner-operator consumes roughly 24,000 gallons of fuel every year. Diesel fuel can account for 25 percent or more of a trucking business’s operating expenses. At an average of $4.215 per gallon, it costs about $40,000 in diesel fuel alone to operate a typical Class 8 tractor truck. Since owner-operators drive more miles, that number may be closer to $70,000 for them.

Taking the lower number of $40,000 a year for fuel, the ReVolt system can save operators about $16,000 a year. For owner-operators, that number is closer to $28,000 a year. Fuel savings are obviously a big deal for truckers — fleet operators often figure their costs down to tenths of a cent per mile. The big benefit as far as CleanTechnica readers are concerned is that a 40 percent reduction in the amount of fuel used translates into a 40 percent reduction in diesel emissions, including the oxides of nitrogen and fine particulate matter that cause diseases in humans.

Built With The American Trucker in Mind

In a press release, ReVolt says its serial hybrid system is designed specifically with the American trucker in mind. With the simple flip of a switch, drivers can change from using a diesel generator on the open road to operating on electricity in areas with zero-emissions mandates. “Drivers should not have to choose between losing their longtime routes because of changing regulatory environments or losing the truck in which they have already made significant investments,” said Gus Gardner, ReVolt Motors founder and CEO. “American truckers want their trucks to reflect their identity, and our retrofit technology allows them to continue driving the trucks they love while still making a living.”

ReVolt’s retrofit solution is a more affordable option than purchasing a new electric truck, which can cost $500,000 before adding customized features and accessories. Retrofitting typically takes place as part of a million-mile overhaul, with conversion costs starting at around $125,000. The ReVolt team installs all components and has developed a proprietary control software along with several design and utility innovations. The serial hybrid system has been designed to scale up easily so the company can grow as market demand increases. The retrofit also eliminates the need for a separate auxiliary power unit to power the sleeper cab without idling the main engine, providing drivers with nearly endless heat and AC.

Beyond reliability, the company says its technology delivers significant environmental benefits. Given that the US trucking industry accounts for 25 percent of the transportation sector’s carbon emissions, ReVolt empowers drivers to adopt a cleaner future for freight transport. The hybrid system can slash carbon emissions by 40%, even with diesel fuel usage, which may allow the retrofitted trucks to qualify for EPA certification as a near-zero emissions solution. “ReVolt’s hybrid system seamlessly charges the truck batteries through the range extender and regenerative braking, so there is no need to waste hours at an EV charger or worry about running out of power before reaching a charging station. This hassle-free solution keeps drivers on the road making money, not stuck on the side,” the company says.

The Takeaway

This is one of those situations where we should not allow the perfect to be the enemy of the good. Would we prefer to wave a magic wand and have all Class 8 trucks in America be battery powered? Of course we would! But they would be much too expensive for some and the charging infrastructure for them is woefully inadequate today. We can debate until the swallows come back to Capistrano the merits of serial hybrid systems, but the bottom like is that this conversion addresses diesel pollution today, not next year or next decade. For those use cases where it makes economic sense, it may be an excellent alternative. ReVolt will be showing off a Peterbilt 379 that has been retrofitted with its serial hybrid technology at the Mid-America Trucking Show next month in Louisville, Kentucky. Stop by and tell them you read about their technology on CleanTechnica.

Chip in a few dollars a month to help support independent cleantech coverage that helps to accelerate the cleantech revolution!

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy