Sign up for CleanTechnica’s Weekly Substack for Zach and Scott’s in-depth analyses and high level summaries, sign up for our daily newsletter, and/or follow us on Google News!

Last Updated on: 24th April 2025, 09:55 am

Tariffs, schmeriffs. That’s the message from automaker Stellantis. The company is laying plans for its future even while fighting tooth and nail for a bigger slice of the US auto market. That includes a solid-state battery roadmap, with the aim of introducing the powerful new technology next year in a fleet of electrified muscle cars.

Another Milestone For The Solid-State Battery Of The Future

Solid-state EV batteries have been a work in progress for the past 10 years or so. Hybrid versions are beginning to appear, but some industry observers generally don’t see a market-ready, all-solid iteration hit the EV industry until the early 2030’s (see more solid-state background here).

Stellantis is among the battery stakeholders jumping the solid-state timeline by a few years. In October last year, the company announced plans to introduce its new Dodge Charger Daytona EV in 2026, featuring an all-solid-state EV battery developed by the US startup Factorial Energy.

“Factorial’s FEST® offers substantial advantages over traditional lithium-ion batteries including higher energy density, reduced weight, improved performance and a potential for further reduction in total vehicle cost over time,” Stellantis explained in a press statement, neatly summing up the advantages of solid-state battery technology as applied to EVs.

One More Step To The Solid-State Battery Of The Future

Stellantis is not putting all its EV battery eggs in one basket, having formed a research partnership with the French Alternative Energies and Atomic Energy Commission last August, leveraging its experience in Li-ion battery technology. Still, the pursuit of all-solid-state batteries appears to be heating up.

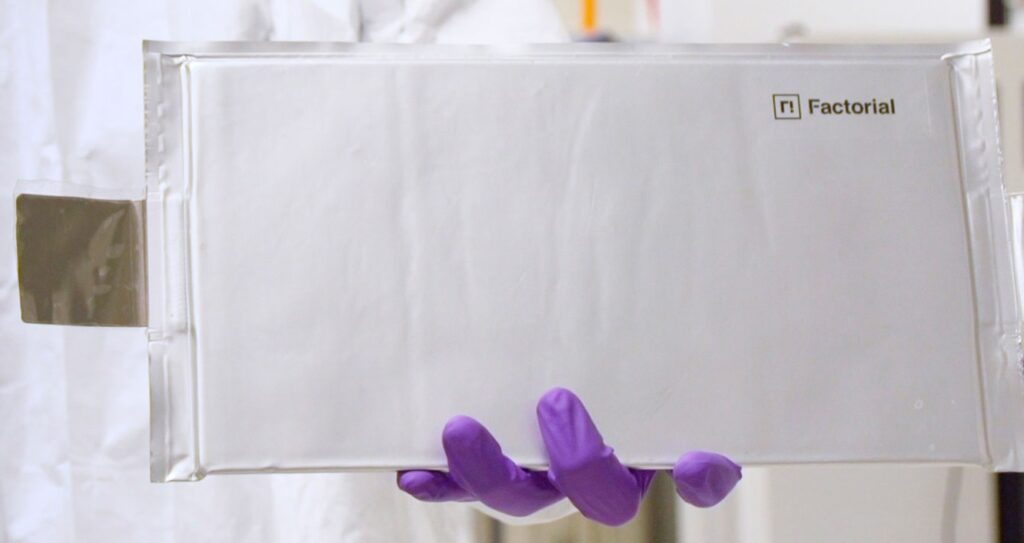

Earlier today, Stellantis and Factorial announced that Factorial’s EV-sized solid-state battery has sailed past a key validation stage. “The validated 77Ah FEST® cells demonstrated an energy density of 375Wh/kg with over 600 cycles progressing towards automotive qualification, a milestone for large-format lithium-metal solid-state battery,” Stellantis explained.

If you caught that thing about “progressing towards automotive qualification,” that’s another way of saying that the new battery is not ready for prime time yet. Still, the validation milestone is a significant one, indicating that the two partners are on the right track. “This breakthrough puts us at the forefront of the solid-state revolution, but we are not stopping there,” vowed Stellantis Chief Engineering and Technology Officer Ned Curic in a press statement.

As described by Stellantis, the new battery can charge from 15% to more than 90% in 18 minutes at room temperature. While 18 minutes is longer than the fast-charging Li-ion batteries of today, the reward is a superior performance payoff.

The 18 minute benchmark is also longer than it takes to fill a coventional sedan, but then again, when was the last time a gas-powered car ever filled itself up? Except for a vanishingly small number of US states that prohibit self service, drivers have to stand by their car, hand on the nozzle to keep the gas flowing, for however long it takes to fill their tank.

EV drivers, meanwhile, can simply plug in and stroll over to the nearest convenience store. Stellantis and other automakers in the Ionna consortium are also leveling up the EV charging experience with lounge-style modeling as well.

First The Dodge Charger, Then The World

Stellantis’s solid-state EV battery plans have been in the public eye since 2021, when the automaker announced a five-year plan to introduce “the first competitive solid-state battery technology” to the EV market.

So far it looks like all is going according to plan for the 2026 launch. Although the Charger muscle car will be the focus of attention, Stellantis and Factorial dropped a hint that the future is wide open.

“By closely collaborating on pack design and leveraging this disruptive technology, Stellantis and Factorial are optimizing battery pack architecture to reduce weight and improve overall system efficiency for seamless integration,” the two companies explain.

“These weight savings directly enhance vehicle range and support more sustainable and affordable EV solutions,” they add.

The Tariff Headaches Are Not Forever

The next steps for Stellantis and Factorial include testing the new solid-state battery under real-world driving conditions, so stay tuned for more on that.

Meanwhile, the US auto market has not been kind to Stellantis. The automaker’s troubles predate the Trump’s unforced trade wars, so it’s not all the fault of the malevolently incompetent Commander-in-Chief who occupies the Oval Office, but the mindless on again, off again juggling of tariffs doesn’t help.

“Production at several Stellantis plants has been scaled back in recent weeks after President Donald Trump’s 25% tariffs on imported cars took effect at the start of April,” The Detroit News reported earlier this week.”

“The automaker paused production at two major assembly plants, one in Mexico and one in Canada, which triggered about 900 temporary layoffs at several of its American powertrain and stamping facilities,” DTN continued.

On a brighter note, yesterday the automotive press reported that Stellantis has restarted its Windsor, Ontario plant, where the Charger EV is produced. The restart enabled about half of the 900 laid-off workers to come back to Stellantis facilities in Michigan and Indiana, which send parts across the border to the Ontario factory.

On an even brighter note, US presidents come and go, and President Trump has only 3.75 years left to batter his way through the US Constitution. When he finally leaves office — peacefully — on January 20, 2029, a growing number of US drivers and fleet owners will still want to buy electric vehicles, and US automakers will still be around to keep the assembly lines rolling.

For that matter, Factorial will still be around to keep the solid-state EV battery momentum going. So will its other A-list partners in the global EV industry, one recent example being the energy storage powerhouse LG Chem. Right around this time last year, Factorial and LG Chem signed a memorandum of understanding to formalize their collaboration on solid-state battery materials.

“The agreement aims to strengthen cooperation in the field of next-generation battery materials and secure future competitive advantage by combining LG Chem’s battery material capabilities and Factorial’s next-generation battery material and process innovations,” Factorial explained.

“Upon successful completion of the project, the two companies agreed to further discuss technology licensing and material supply to maintain a strategic partnership for market leadership,” they added.

As for those pesky tariffs, Republican leadership in Congress could clamp down on President Trump’s ham-handed destruction of the normal order of federal business, if they felt so inclined. After all, Congress is a co-equal branch of government under the Constitution. If you have any thoughts about that, drop a note in the comment thread. Better yet, find your representatives in Congress and let them know what you think.

Photo (cropped): Tariffs or not, Stellantis is sticking with its plan to electrify a fleet of Dodge Charger muscle cars with a powerful new solid-state battery from the US startup Factorial (courtesy of Stellantis).

Whether you have solar power or not, please complete our latest solar power survey.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy